LABORATORY: CNR ISPC

NAME OF THE INSTRUMENT

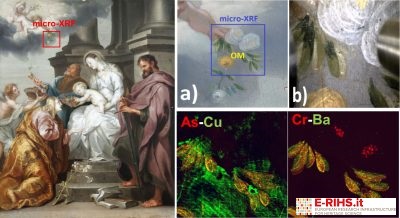

Scanner MICRO-XRF developed at CNR ISPC XRAYLab

GENERAL DESCRIPTION

Micro-XRF mapping is a non-destructive analytical technique based on scanning the sample surface using an X-ray beam strongly focused on the micrometric scale that provides images of elemental distributions with high lateral resolution.

The micro-XRF technique is non-destructive, it can be applied in situ and it is indicated for all those applications in which elemental analysis of materials is aimed at studies of provenance, nature of materials and their state of conservation, manufacturing technique or artistic process. For example, the technique can be used in the search for platinum metals (PGM) in native gold archaeological objects or for studying the artist's brushstrokes in a pictorial composition.

Micro-XRF technique is based on irradiation of the sample surface by continuous scanning with speeds of up to 50mm/sec with a primary X-ray beam with dimensions of the order of 10 microns over an area of 50x50cm2. Given the size of the scanning area, for the first time the micro-XRF technique can also be applied in situ on macroscopic contexts. The X-ray fluorescence emitted by the atomic species of which the sample is composed is suitably revealed as a function of location by a multi-detector system (up to 6 elements) that allows to operate with great efficiency and, consequently, with residence times per pixel of the order of ms.

This feature drastically reduces measurement times. Investigations are videos driven by a high-resolution optical microscope, and images of elemental distributions in studio samples are provided and processed in real time, already during measurement. All materials of inorganic nature can be investigated. Optimal cases of application are: pictorial works on any support, even large ones, metals (even small decorated or engraved objects), painted or glazed ceramics, mineralogical or petrographic material, etc.

TECHNICAL DESCRIPTION

The micro-XRF mobile scanner developed at XRAYLab laboratory is a mechatronic system operating in real-time technology. The system consists of a spectrometric measuring head equipped with a microfocus X-ray tube with a 30W Mo anode coupled with a focusing polycapillary lens. A second primary source of X-rays with Cr anode can be alternating with rh's for better acquisition of images of chemical elements with spectroscopic lines in the low energy region. In addition, the combined use of the two sources allows to separate the distributions of the same chemical element present at different stratigraphic depths of the work. X fluorescence induced by primary radiation is revealed in event mode by a multi-detector system that contains up to 6 50mm2 SDD and energy resolution <130eV at 5.9 keV, operating in parallel. The spectrometric head is mounted on a 3-axis system (XYZ) with a stroke of 50x50x20cm3 that allows the scanning to be carried out in continuous mode at high speed (up to 50 mm/sec) and with a holding time per pixel up to 1msec.

The system is equipped with a central CPU for the control of measurement operating parameters and darkening systems. The CPU handles: the scan sequence; automatically adjusts the parameters of the X source and detectors to avoid degradation of dead time and energy resolution in the XRF spectra of individual pixels; manages a 750 frames/sec laser interferometer for dynamic measurement distance correction, so as to avoid accidental shocks of the scanner with the work in question; preserve scan coordinates so that analysis resumes from the same location in case of prolonged pauses or system downtime (e.g. night breaks). In addition, the CPU operates dynamic spectra-pixel analysis by applying an accurate fit procedure and providing elemental images in real-time without artifacts. The scanning system is also equipped with software for real-time image analysis through which it is possible to correlate images (RGB), apply logical-mathematical tools, apply statistical analysis (e.g. PCA, ICA and NNMF), generate scatter-plots and export individual XRF spectra by selecting any area (ROI) of the image. The scanner can be assembled in two different spectrometric head configurations allowing to analyze large surfaces that can be placed both vertically and horizontally.

Referent:

Paolo Romano francescopaolo.romano@cnr.it